Speed Edge Formwork

Speed Edge Formwork is constructed from galvanized steel sheets, designed for use in base and floor slabs. It is offered in a standard length of 2.25 metres and heights ranging from 150mm to 500mm.

| Product Code | Height (mm) | Base (mm) | Stirrup (qty) | Thickness (mm) | Length (mtr) |

|---|---|---|---|---|---|

| SEF150 | 150 | 100 | 5 | 0.7 | 2.25 |

| SEF160 | 160 | 100 | 5 | 0.7 | 2.25 |

| SEF200 | 200 | 120 | 6 | 0.7 | 2.25 |

| SEF250 | 250 | 150 | 6 | 0.7 | 2.25 |

| SEF300 | 300 | 180 | 7 | 0.7 | 2.25 |

| SEF350 | 350 | 210 | 7 | 1.2 | 2.25 |

| SEF400 | 400 | 240 | 8 | 1.2 | 2.25 |

| SEF450 | 450 | 270 | 9 | 1.2 | 2.25 |

| SEF500 | 500 | 300 | 10 | 1.2 | 2.25 |

| SEF600 | 600 | 360 | 10 | 1.2 | 2.25 |

Benefits

- Self-supporting design for heights up to 500mm

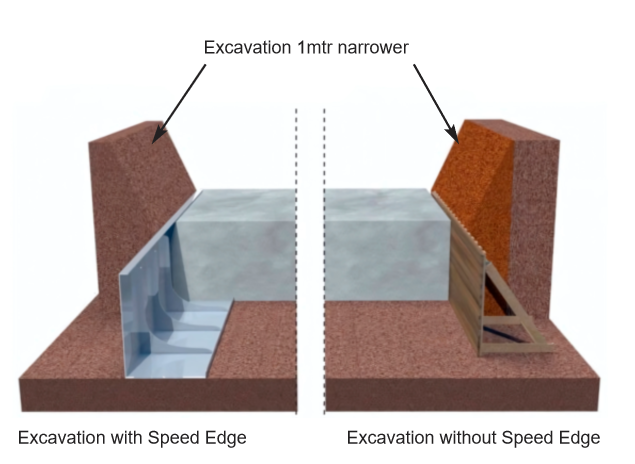

- Reduces excavation requirements and speeds up assembly

- Corners can be easily shaped with simple bending techniques

- Ideal for creating intricate slab designs with minimal effort

- No need for stripping after installation

- Can be installed without requiring heavy machinery like cranes

Installation

Step 1

Fixing

Installation of SEF on the ground. (If SEF is being installed on bedding concrete, nails should be used instead of hooks).

Step 3

Corners

Create corners by cutting the sheet metal base and bending the unit on site.

Step 2

Joining

Joints are installed by simply pushing together the units with 3-4 cm overlap.

Step 4

Pouring

Concreting of foundation slab.

Associated Products

Associated Products